Heptanoic Anhydride | 626-27-7

Cas No :

626-27-7

Form :

Liquid

Molecular Weight :

242.36 G/Mol

Molecular Formula :

C14H26O3

Melting Point :

-15 °C

Boiling Point :

170 °C

Solubility :

Poorly Soluble In Water; Soluble In Organic Solvents (Dichloromethane, Chloroform, Diethyl Ether)

Flash Point :

70 °C

Description :

Overview of Heptanoic Anhydride

Heptanoic Anhydride is a specialised industrial organic acid anhydride used as a reactive intermediate in controlled chemical manufacturing processes. It is typically supplied as a clear to pale yellow liquid and is valued for its acylation efficiency, controlled reactivity, and compatibility with industrial synthesis systems.

As an industrial chemical, Heptanoic Anhydride is used in chemical intermediates manufacturing, specialty resins, surface-active agents, and advanced industrial formulations, where precise reaction control and consistent quality are essential.

Applications of Heptanoic Anhydride

Chemical Manufacturing & Industrial Synthesis

Heptanoic Anhydride is extensively used as an acylating agent and reaction intermediate in industrial organic synthesis. It supports controlled esterification and derivatisation reactions in large-scale chemical processing. It is commonly evaluated alongside Acetic Anhydride, Propionic Anhydride, and Fatty Acid Derivatives in synthesis systems.

Specialty Resins & Industrial Formulations

In specialty industrial formulations, Heptanoic Anhydride is used to modify resins, intermediates, and functional compounds, contributing to controlled molecular structure and performance characteristics required in industrial products.

Surface-Active & Functional Chemical Systems

Heptanoic Anhydride is applied in the manufacture of surface-active agents and functional industrial chemicals, where medium-chain acyl groups are required to achieve specific performance properties in controlled industrial environments.

Safety & Handling Guidelines

-

Store in a cool, dry, and well-ventilated area

-

Protect from moisture and direct contact with water

-

Keep containers tightly sealed and clearly labelled

-

Avoid inhalation of vapours and contact with skin or eyes

-

Use protective gloves, goggles, face shield, and suitable industrial clothing

-

Handle strictly under controlled industrial conditions

-

Dispose of waste and packaging according to regulatory guidelines

Where to Buy Heptanoic Anhydride?

Heptanoic Anhydride Manufacturer

Heptanoic Anhydride is manufactured for industrial-grade applications requiring controlled purity, consistent reactivity, and reliable performance in chemical processing industries.

Heptanoic Anhydride Supplier & Distributor

Heptanoic Anhydride is supplied in bulk and industrial packaging formats for manufacturers requiring dependable quality and regulated handling. Buy Heptanoic Anhydride from Chemicalbull Pvt. Ltd., a trusted industrial chemicals supplier and distributor, supporting customers with reliable sourcing, documentation, and compliant logistics.

MSDS for Heptanoic Anhydride

The MSDS for Heptanoic Anhydride provides detailed information on chemical hazards, safe handling practices, storage conditions, exposure controls, first-aid measures, and emergency response procedures. Always review the MSDS before industrial use.

Frequently Asked Questions (FAQs)

What is the chemical formula of Heptanoic Anhydride?

The chemical formula of Heptanoic Anhydride is C₁₄H₂₆O₃.

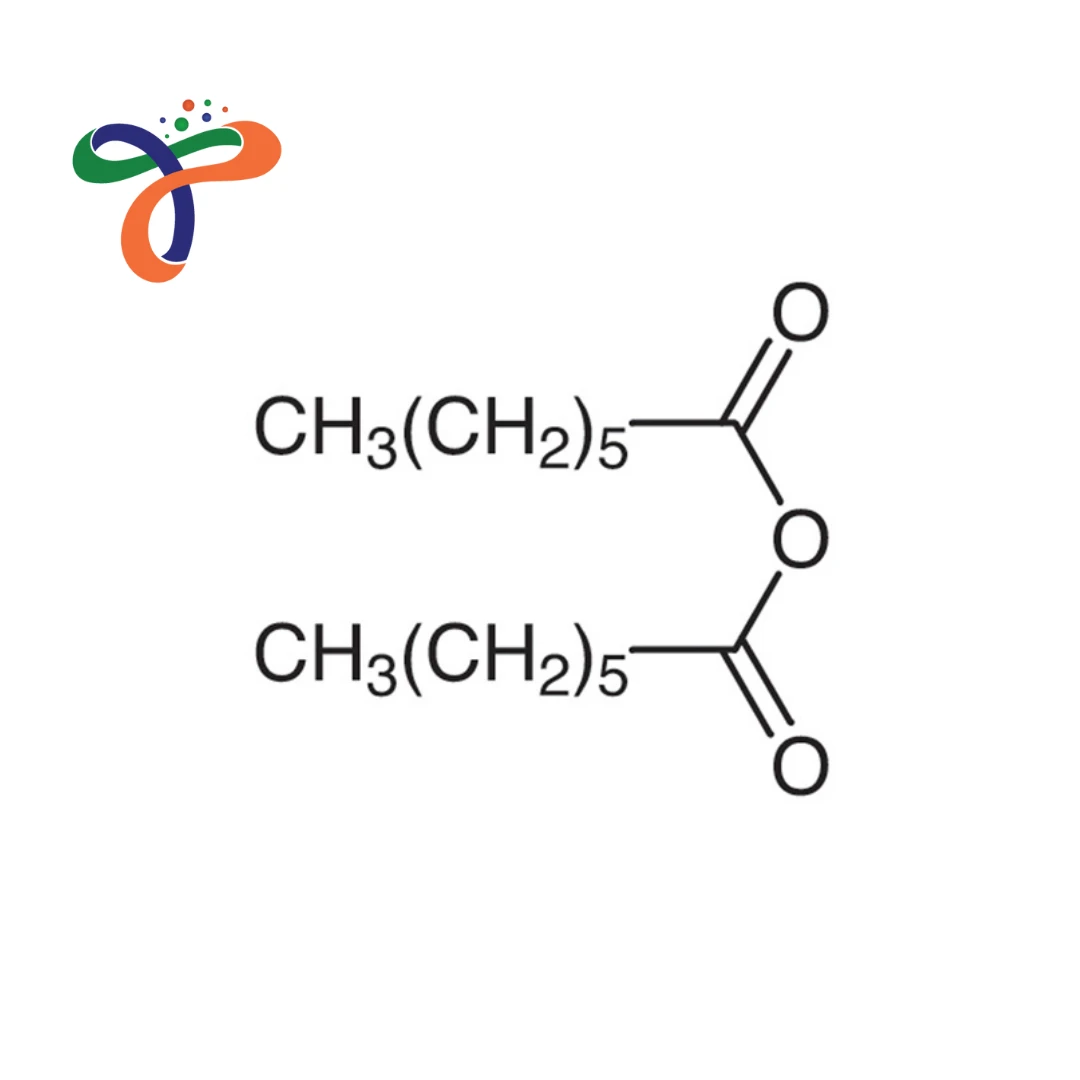

What is the structure of Heptanoic Anhydride?

Heptanoic Anhydride consists of two heptanoic acid chains linked through an anhydride functional group, giving it characteristic acylating properties.

What is Heptanoic Anhydride used for?

It is used in industrial organic synthesis, specialty chemical manufacturing, resin modification, and functional chemical systems.

How is Heptanoic Anhydride synthesised?

Heptanoic Anhydride is typically synthesised through controlled dehydration of heptanoic acid or reaction of acid chlorides under industrial conditions.

Is Heptanoic Anhydride hazardous?

Yes, Heptanoic Anhydride is reactive and moisture-sensitive and may cause irritation. Proper PPE, ventilation, and strict adherence to MSDS guidelines are required.