Zirconium Octoate

Form :

Solid

Molecular Weight :

664.05 G/Mol

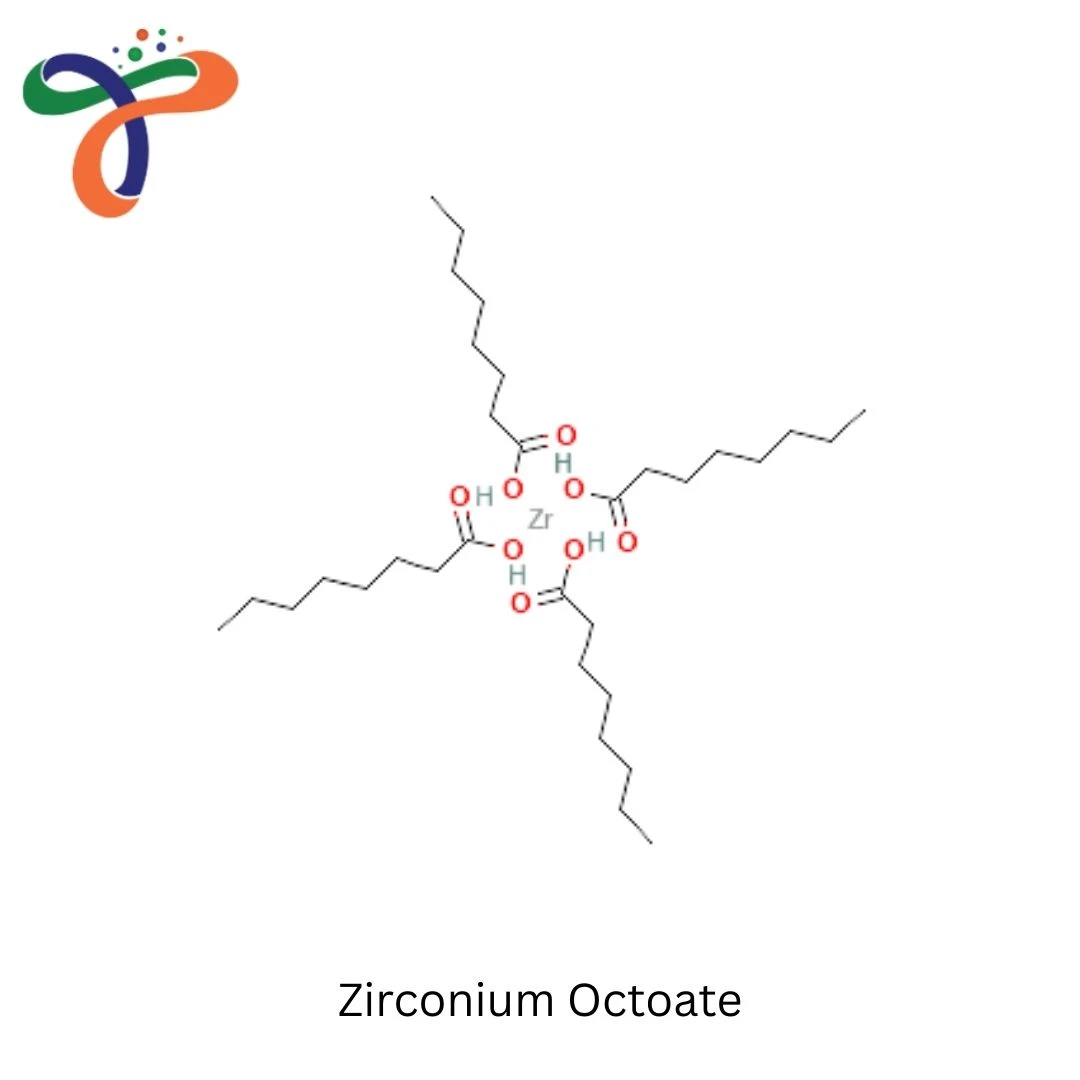

Molecular Formula :

C32H64O8ZR

Boiling Point :

350 °C

Melting Point :

180 °C

Flash Point :

230 °C

Solubility :

Insoluble In Water; Soluble In Nonpolar Organic Solvents Such As Xylene And Toluene

Description :

Overview of Zirconium Octoate

Zirconium Octoate is a high-performance metal-organic compound widely used as a curing agent, catalyst, and crosslinking promoter in coatings, paints, inks, and polymer formulations. It is a light yellow to amber liquid, soluble in organic solvents, and valued for its ability to improve drying speed, hardness, and adhesion in industrial applications. Its chemical structure features zirconium coordinated with octoate ligands, providing excellent stability and reactivity for various resin systems.

In coatings and speciality formulations, Zirconium Octoate is commonly used in alkyd resins, polyurethane coatings, and automotive paints to enhance film properties and durability. It is also compatible with other industrial chemicals such as Zirconium Oxide, Zinc Sulphide, Titanium Dioxide, and Aluminium Stearate available on ChemicalBull, which allows formulators to create robust, high-performance coating and material systems.

Applications of Zirconium Octoate

Coatings & Paints

-

Used as a drying and crosslinking agent in alkyd, polyurethane, and epoxy coatings

-

Improves film hardness, chemical resistance, and adhesion

-

Enhances drying time for commercial and industrial coatings

Inks & Printing Applications

-

Acts as a catalyst in ink formulations for better curing and durability

-

Supports high-quality print stability and scratch resistance

Polymer & Resin Systems

-

Promotes crosslinking in resins and polymer composites

-

Improves mechanical strength and thermal stability

-

Enhances the overall performance of speciality polymer materials

Industrial & Speciality Uses

-

Functions as a stabiliser and promoter in advanced chemical formulations

-

Compatible with other metal-based additives for enhanced performance

Safety & Handling Guidelines

-

Use gloves, protective clothing, and eye protection during handling

-

Avoid inhalation of vapours or direct contact with skin and eyes

-

Store in a cool, dry, and ventilated area, away from moisture and strong oxidizers

-

Keep containers tightly sealed when not in use

-

Follow SDS and standard industrial chemical safety procedures

Where to Buy Zirconium Octoate?

Zirconium Octoate Manufacturer

ChemicalBull supplies high-quality Zirconium Octoate for industrial coatings, inks, and resin applications.

Zirconium Octoate Supplier & Distributor

-

Bulk and customised packaging options

-

Export-grade material with COA, TDS & MSDS

-

Reliable supply for domestic and international markets

-

Trusted chemical supplier for industrial and speciality metal-organic compounds

Zirconium Octoate MSDS

The Material Safety Data Sheet (MSDS) provides guidance on safe handling, storage conditions, exposure limits, and emergency measures. Always consult the MSDS before formulation or industrial use.

Frequently Asked Questions (FAQs)

-

What is Zirconium Octoate used for?

It is mainly used as a drying agent, crosslinking promoter, and catalyst in coatings, paints, inks, and polymer formulations. -

Is Zirconium Octoate compatible with resins?

Yes, it works effectively in alkyd, epoxy, and polyurethane resins to improve hardness, adhesion, and durability. -

How should Zirconium Octoate be stored?

Store in a cool, dry, ventilated place, away from moisture, heat, and oxidising agents. -

Can it be used in industrial inks?

Yes, it enhances curing, scratch resistance, and durability in industrial and printing inks. -

Is Zirconium Octoate hazardous?

It should be handled with protective equipment following SDS guidelines to avoid exposure or contact.