Sodium Vinylsulfonate | 3039-83-6

Cas No :

3039-83-6

Form :

Solid

Molecular Weight :

130.09 G/Mol

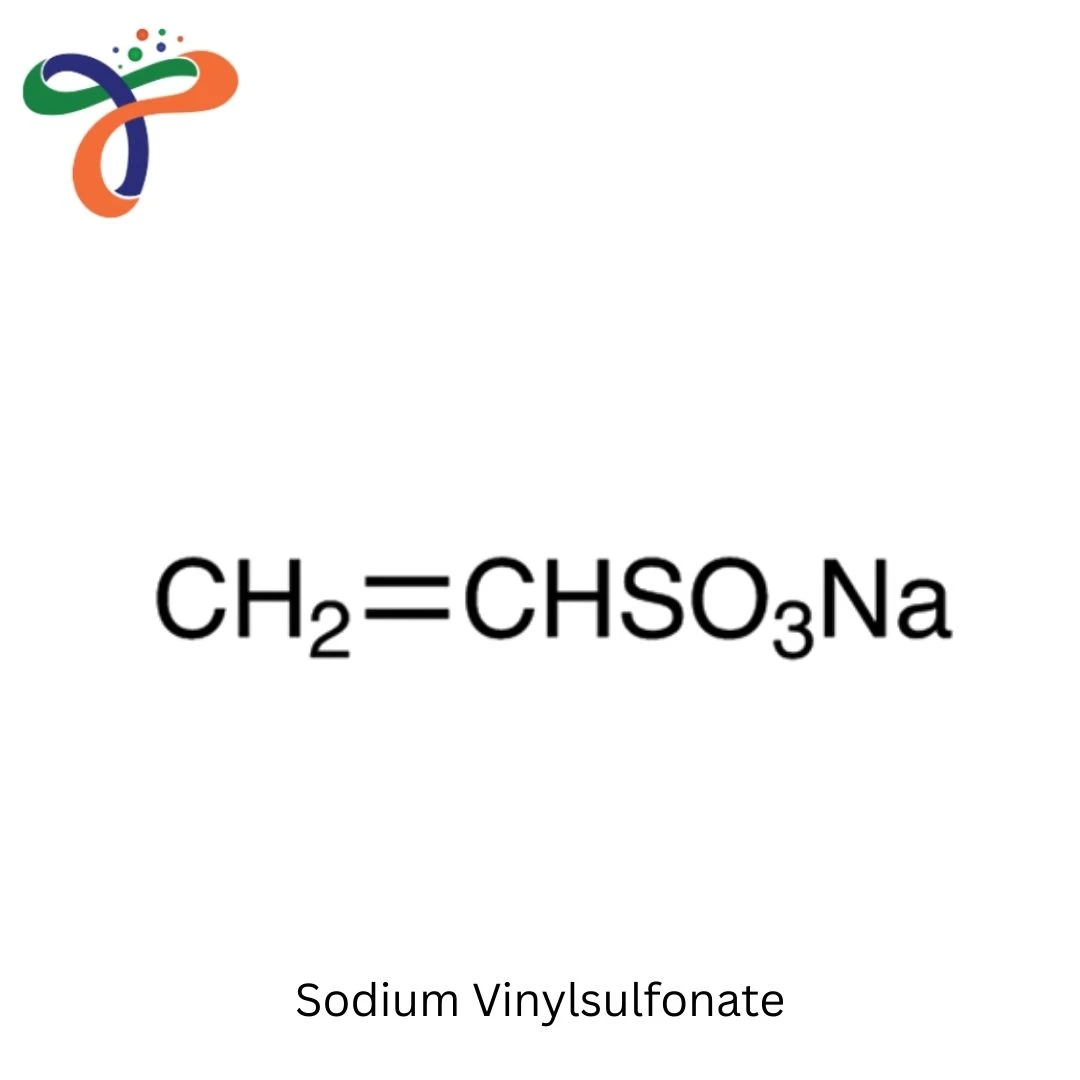

Molecular Formula :

C2H3NAO3S

Melting Point :

140 °C

Boiling Point :

300 °C

Solubility :

Soluble In Water

Flash Point :

180 °C

Description :

Overview of Sodium Vinylsulfonate

Sodium Vinylsulfonate is an industrial sulfonated monomer widely used in manufacturing processes where high anionic charge density, water solubility, and controlled polymer reactivity are required. It is typically supplied as a white to off-white solid or aqueous solution and is valued for its strong sulfonate functionality and vinyl reactivity, which enable efficient copolymerisation in industrial systems.

Sodium Vinylsulfonate is used primarily to make the polymer synthesizer, special chemical formulations, as well as industrial processing in which the stability of the dispersion, enhanced adhesion and improved chemical resistance are crucial.

Applications of Sodium Vinylsulfonate

Polymer & Copolymer Manufacturing

Sodium Vinylsulfonate is widely employed as a comonomer in the manufacture of copolymers and polymers to introduce sulfonate-containing elements into chains of polymers. This improves water solubility, ionic character, and adhesion properties. It is usually evaluated along with Acrylic Acid or polyacrylamide in polymer chemistry.

Chemical Manufacturing & Industrial Intermediates

In the chemical industry, Sodium Vinylsulfonate is used when controlled reactivity of vinyl and anionic function is needed to ensure the production of intermediate products. It provides consistent polymerisation and dependable batch quality.

Surface Treatment & Specialty Industrial Formulations

The sodium vinylsulfonate ingredient is utilized in special industrial formulations that require improved contact with the surface, stability of dispersion, and chemical resistance. It is a key ingredient in enhancing the performance of industrial processing systems.

Paper, Textile & Industrial Processing

The compound is also used in paper and textile-related industrial processing where sulfonated polymers improve binding efficiency, dispersion, and processing stability.

Safety & Handling Guidelines

- Keep in a cool, dry, well-ventilated location.

- Seal containers tightly to stop the absorption of moisture

- Avoid breathing in aerosols or dust during handling

- Avoid direct contact with the eyes and prolonged skin exposure

- Use protective gloves, goggles, and suitable industrial clothing

- Maintain proper ventilation during processing

- Dispose of material and packaging according to local regulations

Where to Buy Sodium Vinylsulfonate?

Sodium Vinylsulfonate Manufacturers in India

Manufacturers of sodium vinylsulfonate in India provide industrial-grade materials for chemical, polymer, paper, and specialty manufacturing with bulk packaging and document assistance.

Sodium Vinylsulfonate Supplier & Distributor

Sodium Vinylsulfonate can be purchased in industrial-grade quantities to manufacturers needing dependable quality and a constant supply. Being an industrial chemicals distributor, Chemicalbull Pvt. Ltd. assists customers by providing consistent sourcing and standardized documentation for industrial needs.

MSDS for Sodium Vinylsulfonate

MSDS for Sodium Vinylsulfonate contains complete information about safe handling procedures and the storage environment, exposure control in the first-aid procedure, as well as emergency procedures for responding. Always read the MSDS prior to industrial use.

Frequently Asked Questions (FAQs)

-

What is Sodium Vinylsulfonate used for?

Sodium Vinylsulfonate is used in polymer and copolymer manufacturing, chemical intermediates, surface treatment formulations, paper processing, and specialty industrial applications. -

Is Sodium Vinylsulfonate water-soluble?

Yes, Sodium Vinylsulfonate is highly water soluble, making it suitable for aqueous polymerisation and solution-based industrial processes. -

Is Sodium Vinylsulfonate hazardous?

Sodium Vinylsulfonate must be handled according to standard safety guidelines. Avoid direct contact. Use the appropriate PPE.