Polypropylene | 9003-07-0

Cas No :

9003-07-0

Form :

Solid

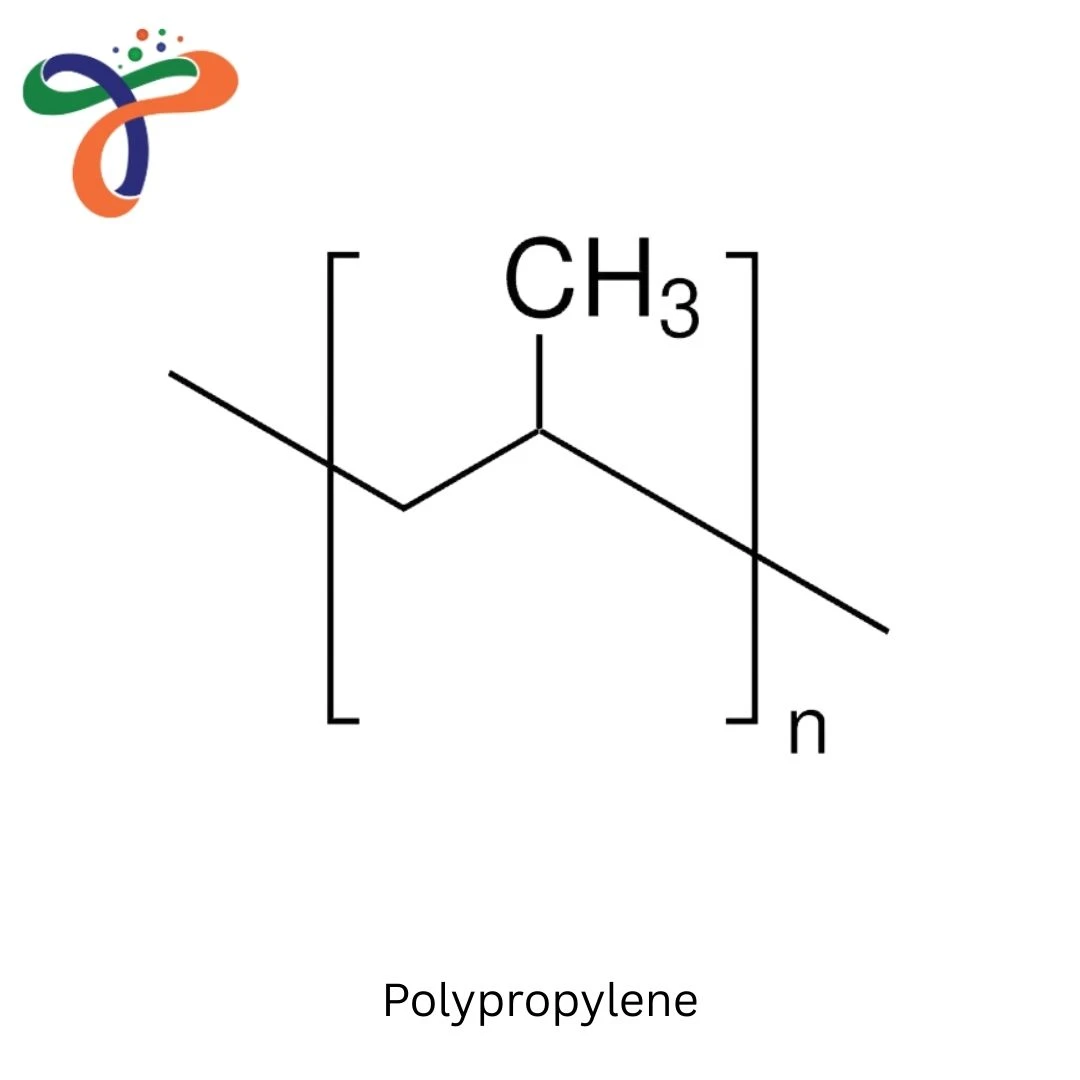

Molecular Formula :

C3H6

Melting Point :

158 - 170 °C

Boiling Point :

120 - 132 °C

Description :

Overview of Polypropylene

Polypropylene is an extensively used thermoplastic polymer renowned due to its superior mechanical and chemical strength and lightness. It's one of the main materials utilized for Plastic & Rubber Chemicals due its wide-ranging application in automotive, packaging, industrial and consumer applications.

For non-technical users, polypropylene plastic can be understood as a strong yet flexible plastic used in everyday items such as containers, automotive parts, household goods, and industrial components. Its balance of durability, heat resistance, and cost-effectiveness makes it a preferred choice in large-scale manufacturing.

Polypropylene is often processed with additives and processing aids such as Cobalt Octoate, Zinc Stearate, and 1,4-Butanediol to improve processing efficiency, surface finish, and performance of finished polypropylene products.

Explore related materials on our Categories Page, understand industrial applications on the Application Page, or visit our Home Page for our complete plastic and chemical portfolio.

Applications of Polypropylene

Packaging & Consumer Goods

Polypropylene is used for food containers, caps, bottles, packaging films, and household items because it resists chemicals and does not absorb much moisture.

Automotive & Industrial Components

Polypropylene is common in car interiors, battery cases, and industrial parts where strength, heat resistance, and light weight are important.

Textiles & Fibers

It is found in non-woven fabrics, carpets, ropes, and geotextiles because it is durable and resists chemicals and moisture.

Medical & Laboratory Products

Polypropylene is often chosen for medical syringes, containers, and lab equipment because it is stable, can be sterilized, and is considered safe.

Key Properties of Polypropylene

- Polypropylene melts at about 160 to 170°C.

- Polypropylene has a density of about 0.90 to 0.91 g/cm³, which makes it one of the lightest commercial plastics.

- It is highly resistant to chemicals and wear from repeated use.

- Polypropylene is a good electrical insulator.

- It is easy to shape using methods like injection molding, extrusion, and thermoforming.

Safety & Handling Guidelines

Storage & Handling

- Store polypropylene in a clean, dry place.

- Keep it away from direct heat and open flames.

- Avoid letting dust or moisture contaminate it during storage.

- Follow standard guidelines for handling and processing plastics.

- Dispose of any waste material according to local environmental rules.

Where to Buy Polypropylene?

Manufacturer

Polypropylene is manufactured for use in packaging, automotive parts, industrial components, textiles, and medical applications where consistent quality and performance are essential.

Supplier & Distributor

As a reliable supplier and distributor, we offer Polypropylene in bulk and industrial-grade packaging. We support manufacturers with consistent supply, quality assurance, and scalable volumes for production needs.

Polypropylene MSDS

The Material Safety Data Sheet (MSDS) for polypropylene gives important details about safe handling, storage, temperature limits, and what to do in emergencies. It is a good idea to read the MSDS before using polypropylene in industry.

Frequently Asked Questions (FAQs)

1. what is polypropylene used for

Polypropylene is used in packaging, automotive parts, household goods, textiles, medical products, and various industrial applications due to its strength and chemical resistance.

2. is polypropylene recyclable

Yes, polypropylene is recyclable and is commonly identified with recycling code 5. It can be reprocessed into new plastic products.

3. Is polypropylene safe for food contact?

Yes, polypropylene is widely approved for use with food because it is non-toxic, resists chemicals, and does not easily release harmful substances.