Polytetramethylene Ether Glycol | 25190-06-1

Cas No :

25190-06-1

Synonyms :

Form :

Liquid

Molecular Weight :

146.23

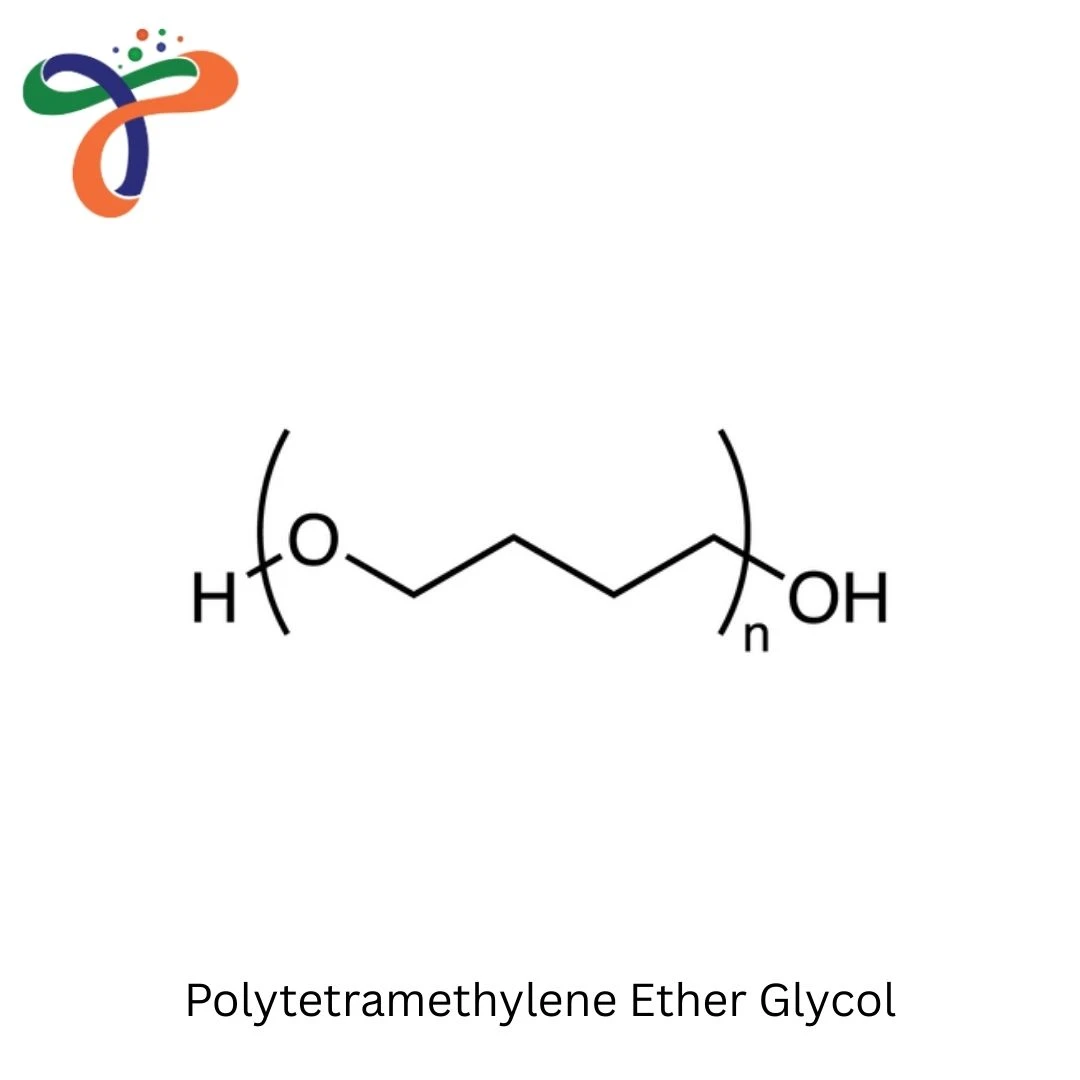

Molecular Formula :

C8H18O2

Melting Point :

28 - 40 °C

Description :

Overview of Polytetramethylene Ether Glycol

Polytetramethylene Ether Glycol, commonly known as PTMEG, is a high-performance polyether diol widely used in elastomers, fibres, and speciality polymer manufacturing. It is valued for its excellent elasticity, flexibility, and resistance to abrasion, making it a critical raw material in advanced polymer systems.

For non-technical buyers, Polytetramethylene Ether Glycol can be understood as a flexible polymer building block that helps materials stretch, recover, and perform reliably under stress. Its ability to enhance softness and mechanical strength makes it especially suitable for applications requiring durability and long service life.

Polytetramethylene Ether Glycol falls under the polyether glycols and polymer intermediates category and is often processed alongside related products such as Polypropylene Glycol (PPG) and Polyethene Glycol (PEG) in flexible polymer manufacturing.

Applications of Polytetramethylene Ether Glycol

Polyurethane Elastomers & Resin Systems

Polytetramethylene Ether Glycol is extensively used as a soft segment in polyurethane elastomers and resins. It delivers excellent elasticity, low-temperature flexibility, and abrasion resistance. These properties make it suitable for industrial rollers, seals, belts, and moulded elastomeric components, often formulated with isocyanates and intermediates used in polyurethane resin production.

Spandex Fibres & Elastic Textile Manufacturing

In fibre manufacturing, Polytetramethylene Ether Glycol is a key raw material for producing spandex and other elastic fibres. It provides superior stretch and recovery compared to alternative polyether glycols, making it widely preferred over standard polyester polyols in high-performance textile applications.

Coatings, Adhesives & Sealants

PTMEG is used in speciality coatings, adhesives, and sealants to improve flexibility, impact resistance, and durability. It is commonly formulated with acrylic and polyurethane systems, supporting applications where repeated movement and mechanical stress are involved.

Polymer Blending & Speciality Formulations

In polymer processing, Polytetramethylene Ether Glycol is used in blending and formulation to enhance toughness and resilience. It is frequently used alongside materials such as 2-Ethylhexyl Acrylate and Hydroxyethyl Acrylate in flexible coating and elastomer formulations requiring controlled elasticity and long-term stability.

Safety & Handling Guidelines

-

Store in a cool, dry, and well-ventilated area

-

Keep containers tightly sealed to prevent contamination

-

Avoid prolonged contact with skin and eyes

-

Prevent inhalation of vapours or mists during handling

-

Use appropriate gloves, goggles, and protective clothing

-

Keep away from strong oxidising agents

-

Follow standard polymer material handling practices

-

Dispose of containers according to local regulations

Where to Buy Polytetramethylene Ether Glycol?

Polytetramethylene Ether Glycol Manufacturer

Polytetramethylene Ether Glycol is manufactured for use in polyurethane elastomers, elastic fibres, coatings, and speciality polymer applications requiring consistent molecular weight and reliable performance characteristics.

Polytetramethylene Ether Glycol Supplier & Distributor

Polytetramethylene Ether Glycol is supplied in bulk and industrial-grade quantities for polymer manufacturers, fibre producers, and speciality material processors. It is available for domestic and international markets with dependable supply capabilities and standard quality documentation.

As a reliable polymer raw material supplier, experienced bulk distributor, and industrial sourcing partner, we support manufacturers with consistent access to polyether glycols and related polymer intermediates, ensuring stable quality, scalable volumes, and smooth procurement.

Polytetramethylene Ether Glycol MSDS

The Material Safety Data Sheet (MSDS) for Polytetramethylene Ether Glycol provides detailed information on safe handling, storage conditions, exposure controls, first-aid measures, and emergency response procedures. Users should always review the MSDS before handling or using the product in industrial environments.

Frequently Asked Questions (FAQs)

-

What is Polytetramethylene Ether Glycol used for?

It is mainly used in polyurethane elastomers, spandex fibres, flexible coatings, adhesives, and speciality polymer systems. -

How does PTMEG differ from other polyether glycols?

PTMEG offers superior elasticity, abrasion resistance, and low-temperature performance compared to many conventional polyether glycols. -

Is Polytetramethylene Ether Glycol suitable for textile applications?

Yes, it is a primary raw material in the production of spandex and other elastic fibres used in performance textiles. -

Can PTMEG be used in coating and adhesive formulations?

It is widely used to enhance flexibility, durability, and mechanical stability in coatings, adhesives, and sealants. -

Is Polytetramethylene Ether Glycol available for bulk industrial supply?

Yes, it is commonly supplied in bulk quantities for large-scale polymer, elastomer, and fibre manufacturing operations.