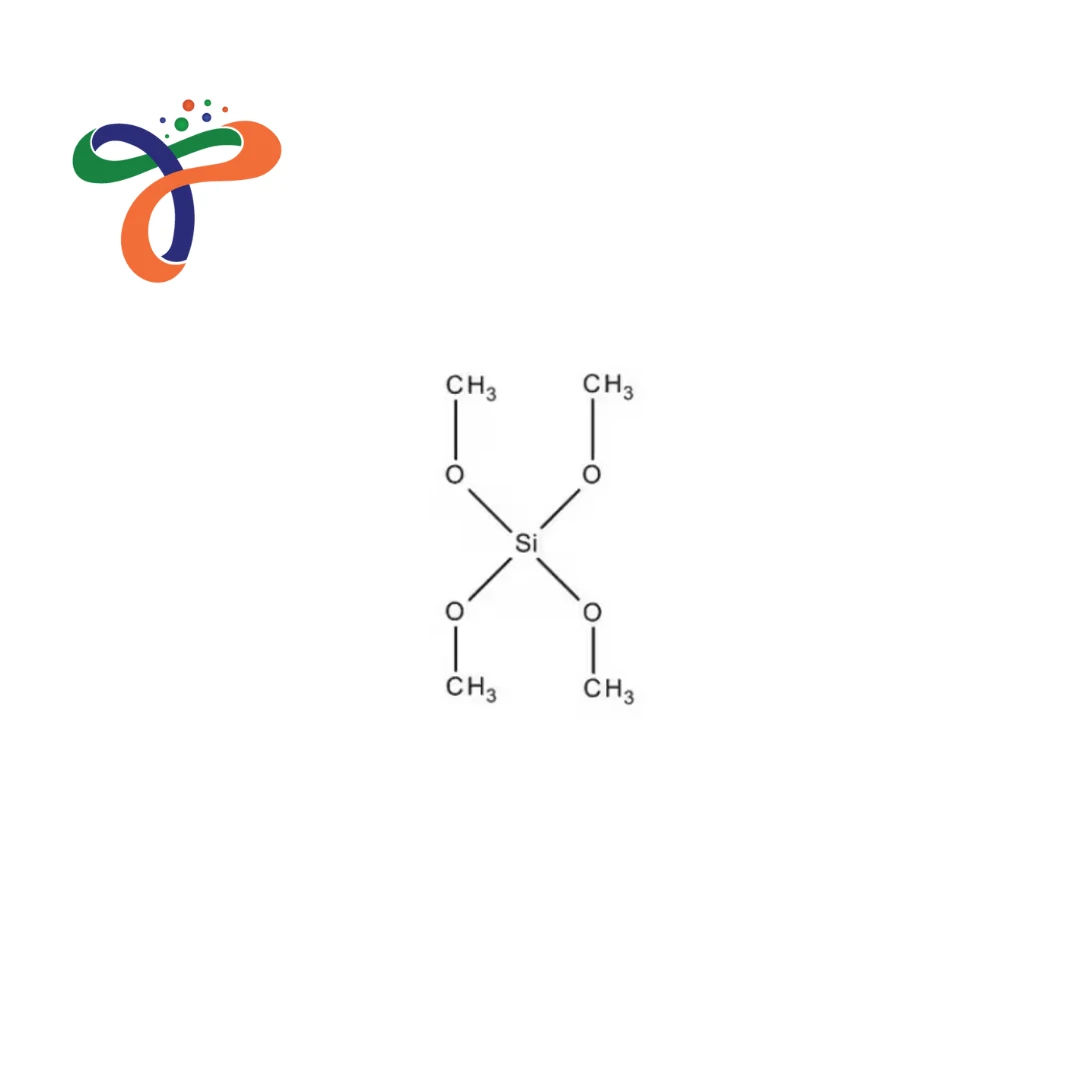

Methyl Silicate | 681-84-5

Cas No :

681-84-5

Form :

Liquid

Molecular Weight :

136.22 G/Mol

Molecular Formula :

C4H12O4SI

Melting Point :

-95 °C

Boiling Point :

125 °C

Solubility :

Insoluble In Water; Soluble In Organic Solvents (E.g., Ethanol, Acetone, Toluene); Hydrolyzes In Moisture

Flash Point :

-5 °C

Description :

Overview of Methyl Silicate

Methyl Silicate is an important organosilicon compound widely used as a binder, crosslinking agent, and precursor for silica formation in coatings, foundry applications, construction chemicals, and speciality industrial formulations. It is commonly supplied as tetramethyl orthosilicate (TMOS) or as polymeric methyl silicate grades, depending on application requirements. Upon hydrolysis, Methyl Silicate forms silica networks that provide hardness, heat resistance, and durability.

In appearance, Methyl Silicate is typically a clear, colourless liquid with good miscibility in organic solvents. It reacts with moisture to form silica and methanol, making it highly effective in applications requiring inorganic bonding and surface strengthening. Due to its reactivity, it is handled in controlled industrial environments.

ChemicalBull supplies industrial-grade Methyl Silicate with controlled purity, consistent reactivity, and reliable batch performance. Each shipment is supported with complete documentation, including MSDS, COA, and technical data sheets.

As a trusted chemical supplier and reliable distributor, ChemicalBull ensures dependable supply for industrial manufacturers. You may also like Ethyl Silicate, Sodium Silicate, Potassium Silicate, and Silicone Resins for related industrial silicate and binder applications available on our site.

Applications of Methyl Silicate

Foundry & Casting Applications

-

Used as a binder in sand moulds and cores

-

Forms strong silica bonds after curing

-

Applied in precision metal casting

Coatings & Protective Treatments

-

Used as a binder in inorganic coatings

-

Enhances hardness and heat resistance

-

Applied to anti-corrosion and heat-resistant coatings

Construction & Stone Consolidation

-

Used for strengthening stone and masonry

-

Improves durability and weather resistance

-

Applied in conservation and repair systems

Chemical & Speciality Manufacturing

-

Used as a precursor for silica formation

-

Supports sol–gel and surface treatment processes

-

Applied in speciality industrial chemical formulations

Safety & Handling Guidelines

-

Handle using gloves, goggles, and appropriate PPE

-

Avoid inhalation of vapours

-

Use in well-ventilated industrial environments

-

Store in tightly sealed containers away from moisture

-

Follow MSDS and standard industrial safety practices

Where to Buy Methyl Silicate?

Methyl Silicate Manufacturer

ChemicalBull supplies industrial-grade Methyl Silicate suitable for foundry binders, coatings, construction chemicals, and speciality industrial applications.

Methyl Silicate Supplier & Distributor

-

Bulk and customised industrial packaging options

-

Export-grade quality with COA, TDS & MSDS

-

Reliable supply across India and international markets

-

Trusted chemical supplier for organosilicon and silicate chemicals

Methyl Silicate MSDS

The Methyl Silicate MSDS provides essential information on safe handling, storage conditions, flammability, and reactivity hazards. Always review the MSDS before bulk handling or industrial use.

Frequently Asked Questions (FAQs)

-

What is Methyl Silicate mainly used for?

It is mainly used as a binder and silica-forming precursor in foundry, coatings, construction, and speciality industrial applications. -

Does Methyl Silicate react with moisture?

Yes, it hydrolyses with moisture to form silica, which provides hardness and bonding strength. -

Is Methyl Silicate suitable for high-temperature applications?

Yes, the silica formed offers excellent heat resistance, making it suitable for high-temperature uses. -

In which industries is Methyl Silicate commonly used?

It is commonly used in foundry casting, coatings, construction chemicals, and speciality manufacturing. -

Is safety documentation provided with the supply?

Yes, every shipment includes a complete MSDS, COA, and technical documentation.