Hydroxyethyl Methacrylate | 868-77-9

Cas No :

868-77-9

Synonyms :

Form :

Liquid

Molecular Weight :

130.14

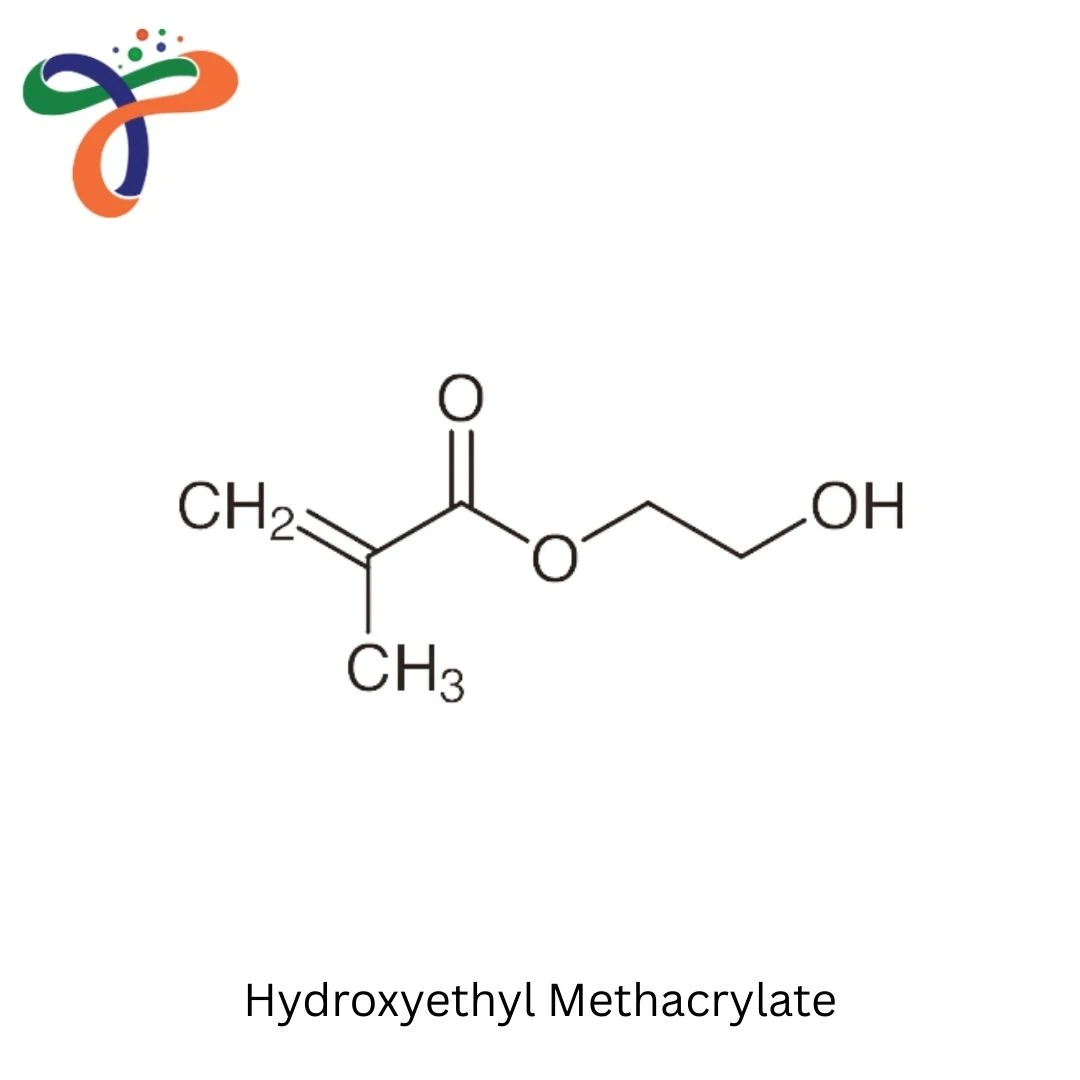

Molecular Formula :

C6H10O3

Melting Point :

12 °C

Boiling Point :

67 °C

Solubility :

Chloroform, Methanol (Slightly)

Flash Point :

106 °C

Description :

Overview of Hydroxyethyl Methacrylate (HEMA)

Hydroxyethyl Methacrylate (HEMA) is a flexible monomer utilized in the rubber chemical and plastic industries to create adhesives, coatings hydrogels, special polymers. It is a good reacted polymer, draws water and makes the polymers stay more elastic, and last for longer.

For those without a technical background, Hydroxyethyl Methacrylate helps plastics and rubbers bond better, absorb moisture, and improve their strength. It is an important ingredient in medical polymers, coatings, and adhesives used in many industries.

In industrial applications, Hydroxyethyl Methacrylate is often combined with chemicals such as Acrylamide, 3-Mercaptopropyl Trimethoxysilane, and Azodicarbonamide to enhance polymerization, adhesion, and final product performance.

Explore related materials on our Categories Page, check industrial applications on the Application Page, or visit our Home Page for the full chemical portfolio.

Applications of Hydroxyethyl Methacrylate

Coatings & Adhesives

HEMA is used in both water-based and solvent-based coatings and adhesives to make them stick better, stay flexible, and last longer.

Hydrogels & Medical Polymers

It is an important part of hydrogels, contact lenses, and medical devices because it works well with water, is safe for the body, and stays flexible.

Specialty Polymer Formulations

Hydroxyethyl Methacrylate products are used in polymer blends to improve moisture absorption, crosslinking, and mechanical strength.

Industrial Chemical Applications

It is used in industrial polymers and resins when you need steady polymer formation, good sticking power, and reliable performance.

Key Properties

-

Hydroxyethyl methacrylate chemical formula: C6H10O3

-

hydroxyethyl methacrylate solubility: Miscible with water, alcohols, and many organic solvents

-

It reacts quickly during free-radical polymerization.

-

It works well with many types of monomers, resins, and polymers.

-

It helps final products stick better, stay flexible, and last longer.

Safety & Handling Guidelines

-

Place in a cool dry and well ventilated area

-

Seal containers well even when not in the use

-

Beware of direct eye and skin contact

-

Avoid inhalation from vapors or mist

-

Wear protective gloves, safety glasses as well as clothes

-

Beware of the heat, sparks and other incompatible materials

-

Utilize the standard chemical handling procedures for industrial use.

-

Waste disposal is governed by the local rules

Where to Buy Hydroxyethyl Methacrylate?

Manufacturer

Hydroxyethyl Methacrylate is made for coatings, adhesives, hydrogels, and specialty polymers where sticking power, flexibility, and water compatibility matter most.

Supplier & Distributor

We supply Hydroxyethyl Methacrylate in bulk and industrial-grade quantities, ensuring consistent quality, reliable supply, and scalable volumes for manufacturers and chemical formulators.

Hydroxyethyl Methacrylate MSDS

The Material Safety Data Sheet (MSDS) gives details on safe handling, storage, exposure limits, first aid, and emergency steps. Please read the MSDS before using or handling this product.

Frequently Asked Questions (FAQs)

1. What is Hydroxyethyl Methacrylate used for?

Hydroxyethyl Methacrylate is used as a monomer in coatings, adhesives, hydrogels, medical devices, and specialty polymers to help them stick better, stay flexible, and work well with moisture.

2. What products have Hydroxyethyl Methacrylate?

You can find it in water-based and solvent-based coatings, adhesives, hydrogels, contact lenses, and special polymer blends.

3. Is Hydroxyethyl Methacrylate water-soluble?

Yes, it mixes well with water and many polar organic solvents, which makes it great for hydrophilic polymer systems.

4. Can HEMA improve adhesion in coatings?

Yes, HEMA enhances surface adhesion and flexibility, making coatings more durable and resistant to cracking.

5. Is Hydroxyethyl Methacrylate safe to handle in industrial use?

Yes, it is safe to handle if you use the right protective gear and follow standard industrial safety steps.