Diphenylguanidine | 0102-06-07

Cas No :

0102-06-07

Form :

Powder

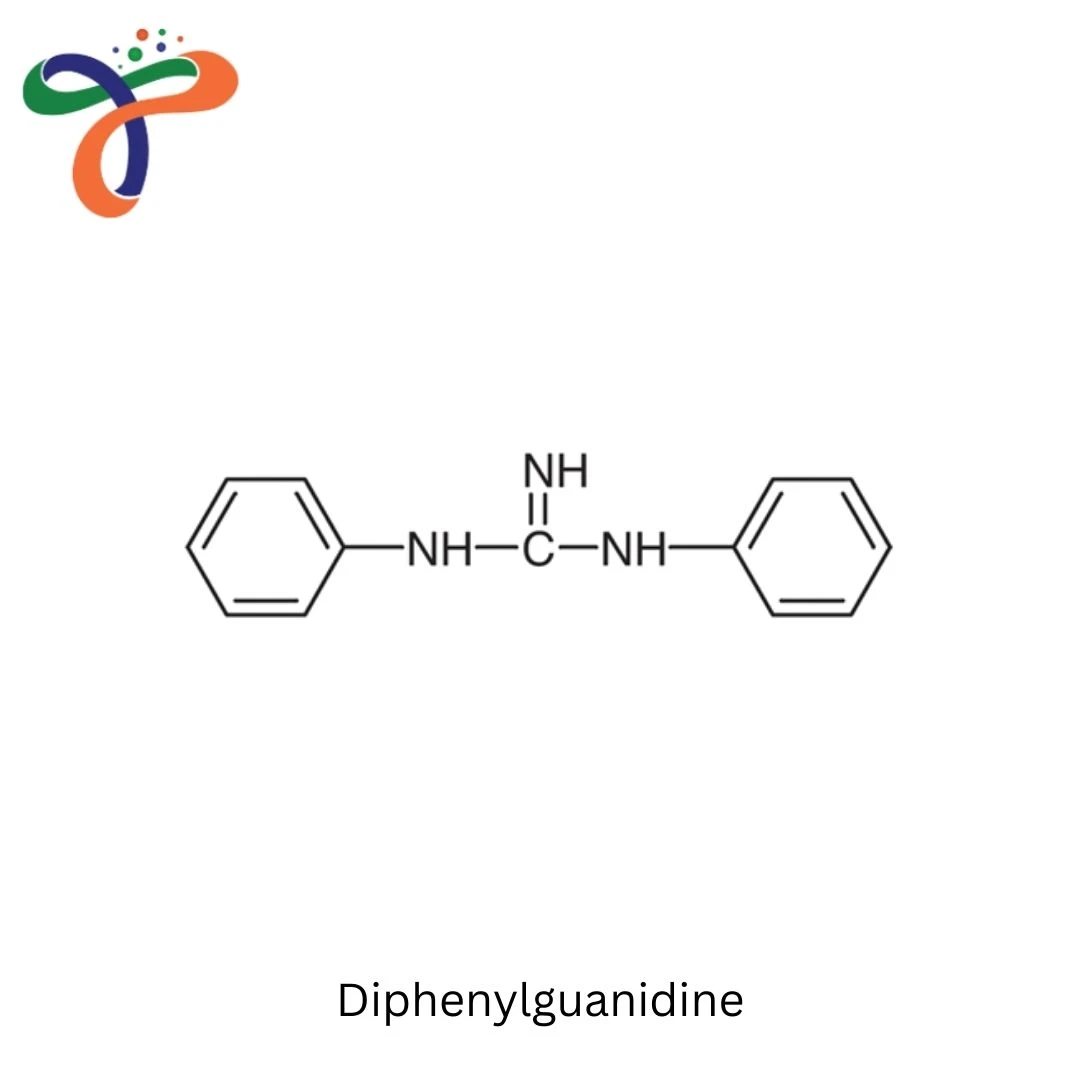

Molecular Weight :

226.28 G/Mol

Molecular Formula :

C13H13N3

Boiling Point :

370 °C

Flash Point :

180 °C

Solubility :

Slightly Soluble In Water; Soluble In Organic Solvents (Benzene, Toluene, Chloroform, Acetone)

Description :

Overview of Diphenylguanidine

Diphenylguanidine powder is a crucial organic chemical that is used in rubber and plastics specifically for its role as an accelerator during the rubber manufacturing process. This powder is fine and crystallized. It assists in accelerating the cure of rubber to strengthen, as well as improve overall performance.

For those without a technical background, Diphenylguanidine powder acts as a booster that helps rubber and plastic products cure well and become stronger and more durable. Its balanced reactivity makes it a good choice for industrial uses where consistent results are important.

Diphenylguanidine is commonly used alongside other industrial chemicals such as Triallyl Cyanurate, Caprolactam, and Polydimethylsiloxane Vinyl Terminated to optimize rubber and polymer formulations.

For more related products, visit our Categories Page, explore real-world uses on our Application Page, or browse our full range on the Home Page.

Applications of Diphenylguanidine

Rubber Processing and Vulcanization

Diphenylguanidine powder can be employed as a secondary accelerator during rubber Vulcanization. It assists in accelerating the cure of rubber and makes it more durable and helps ensure crosslinking is even in the natural as well as synthetic rubber.

The Plastic & Polymer Formulations

In specialty and plastics, Diphenylguanidine supports controlled curing processes and increases thermal stability. It assists manufacturers in achieving consistent quality and reliable performance in processing.

Adhesives & Sealants

Diphenylguanidine is added to some adhesives and sealants to make bonds stronger and longer-lasting. It mixes well with other curing agents and additives.

Industrial Chemical Blends

In specialty chemical blends, Diphenylguanidine helps improve strength and makes processing more stable. It is valued because it behaves predictably and is easy to add to industrial mixes.

Safety & Handling Guidelines

- Store in a cool, dry, and well-ventilated area

- Keep containers tightly closed when not in use

- Avoid prolonged skin and eye contact

- Prevent inhalation of dust

- Use protective gloves, goggles, and suitable clothing

- Keep away from heat and incompatible substances

- Follow standard industrial chemical handling procedures

- Dispose of waste according to local environmental regulations

Where to Buy Diphenylguanidine?

Diphenylguanidine Manufacturer

Diphenylguanidine is made for industrial use in rubber processing, plastics, and specialty chemicals where reliable curing is needed.

Diphenylguanidine Supplier & Distributor

As a trusted supplier, we offer Diphenylguanidine powder in bulk for rubber makers, polymer processors, and specialty chemical companies. We provide a steady supply, consistent quality, and support for large industrial needs.

Diphenylguanidine MSDS

The Material Safety Data Sheet (MSDS) for Diphenylguanidine gives detailed information about safe handling, storage, exposure limits, first aid, and emergency steps. Always review the MSDS before storing, handling, or using this chemical in industry.

Frequently Asked Questions (FAQs)

1. What is Diphenylguanidine used for?

Diphenylguanidine is mainly used as an accelerator in rubber vulcanization and as a curing aid in plastics and polymers. It helps improve strength, durability, and processing efficiency.

2. Is Diphenylguanidine compatible with other rubber chemicals?

Yes, Diphenylguanidine powder works effectively with chemicals such as Triallyl Cyanurate, Caprolactam, and Polydimethylsiloxane Vinyl Terminated in rubber and polymer systems.

3. How should Diphenylguanidine be stored?

Store it in tightly sealed containers in a cool, dry, and well-ventilated place, away from moisture and materials it should not contact.