Allyl Glycidyl Ether | 106-92-3

Cas No :

106-92-3

Synonyms :

Form :

Liquid

Molecular Weight :

114.14 G/Mol

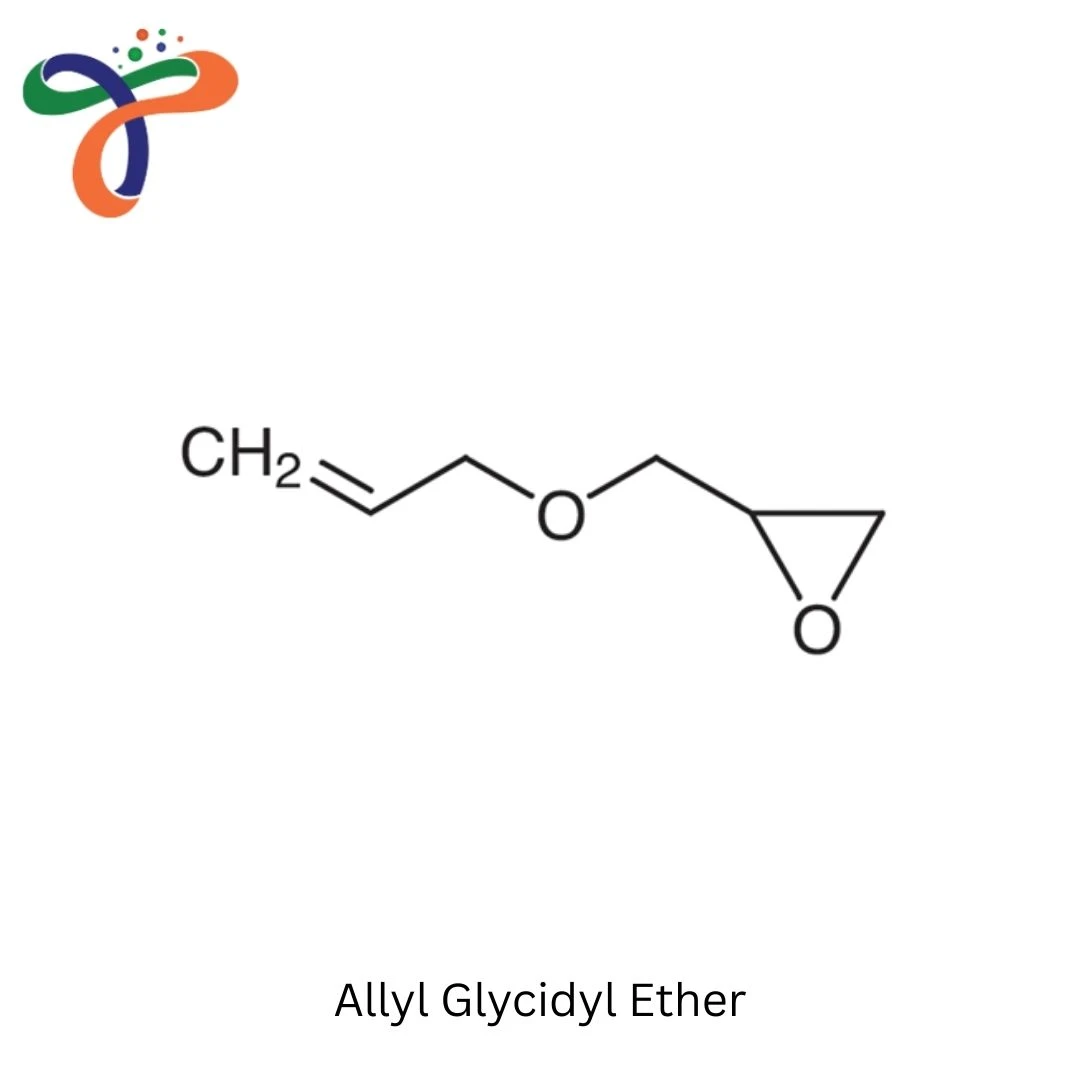

Molecular Formula :

C6H10O2

Melting Point :

-100 °C

Boiling Point :

154 °C

Flash Point :

57 °C

Description :

Overview of Allyl Glycidyl Ether

Allyl Glycidyl Ether can be described as a specific epoxy that can be extensively used in rubber and plastic chemical applications. It has both an epoxy group as well as an allyl component, which can be extremely useful in increasing crosslinking, flexibility and adhesion of polymer systems.

Due to its dual functionality, it is commonly used in epoxy resins, coatings, adhesives, and specialty polymer formulations.

For those without a technical background, Allyl Glycidyl Ether acts as a performance booster. It helps polymers bond more strongly, cure well, and become tougher. It also helps different polymer parts work together, leading to durable, high-quality products.

In industrial formulations, Allyl Glycidyl Ether works effectively with other performance chemicals such as Triallyl Cyanurate, Caprolactam, and Polydimethylsiloxane Vinyl Terminated to ensure consistent processing and reliable product quality.

To explore related products and classifications, visit our Categories Page. For practical industrial uses, check our Application Page, or browse our full range on the Home Page.

Applications of Allyl Glycidyl Ether

Epoxy Resins & Polymer Modification

Allyl Glycidyl Ether is often used as a reactive diluent and modifier in epoxy resins. It makes the resin more flexible, tougher, and better linked, while keeping the curing time about the same.

Coatings & Surface Treatments

In coatings, it helps them stick better to different surfaces, makes the coating more flexible, and adds resistance to chemicals and moisture. This makes it a good choice for industrial and protective coatings.

Adhesives & Sealants

Allyl Glycidyl Ether makes adhesives and sealants stronger and longer-lasting. Its reactive epoxy group helps it bond well with many materials.

Plastic & Rubber Formulations

In plastic and rubber compounds, it helps different ingredients mix better, makes processing easier, and improves the final product’s strength and performance.

Safety and Handling Instructions

- Keep it in a cool, dry, well-ventilated and shady area.

- Make sure containers are tightly sealed even when not being used.

- Do not keep eye or skin contact

- Beware of inhaling vapors and mists

- Make sure you wear protective gloves, goggles, and appropriate clothing

Where to Purchase Allyl Glycidyl Ether?

Manufacturer

Allyl Glycidyl Ether a product made for use in the industrial sector, such as epoxy resins and coatings rubbers, adhesives, plastics and other specialty polymers in which it is necessary to control the reactivity.

Supplier & Distributor

We are a reputable supplier we provide Allyl Glycidyl in bulk to industrial companies as well as specialty formulators. We offer consistent quality, steady supply and assistance for production on a large scale.

Allyl Glycidyl Ether MSDS

The Material Safety Data Sheet (MSDS) for Allyl Glycidyl Ether gives detailed details on safe handling, storage limit of exposure, first aid and the emergency procedures. Always read the MSDS prior to using the chemical in industrial settings.

Frequently Asked Questions (FAQs)

1. What is allyl glycidyl ether used for?

What is allyl glycidyl ether used for? It is mainly used as a reactive monomer and modifier in epoxy resins, coatings, adhesives, plastics, and rubber to improve adhesion, flexibility, crosslinking, and overall polymer performance.

2. Is Allyl Glycidyl Ether compatible with other industrial chemicals?

Yes, it is compatible with chemicals such as Triallyl Cyanurate, Caprolactam, and Polydimethylsiloxane Vinyl Terminated in advanced polymer systems.

3. How should Allyl Glycidyl Ether be stored?

Store it in tightly sealed containers in a cool, dry, and well-ventilated place, away from heat and incompatible materials.