Lithium Silicate | 10102-24-6

Cas No :

10102-24-6

Form :

Powder

Molecular Weight :

89.96 G/Mol

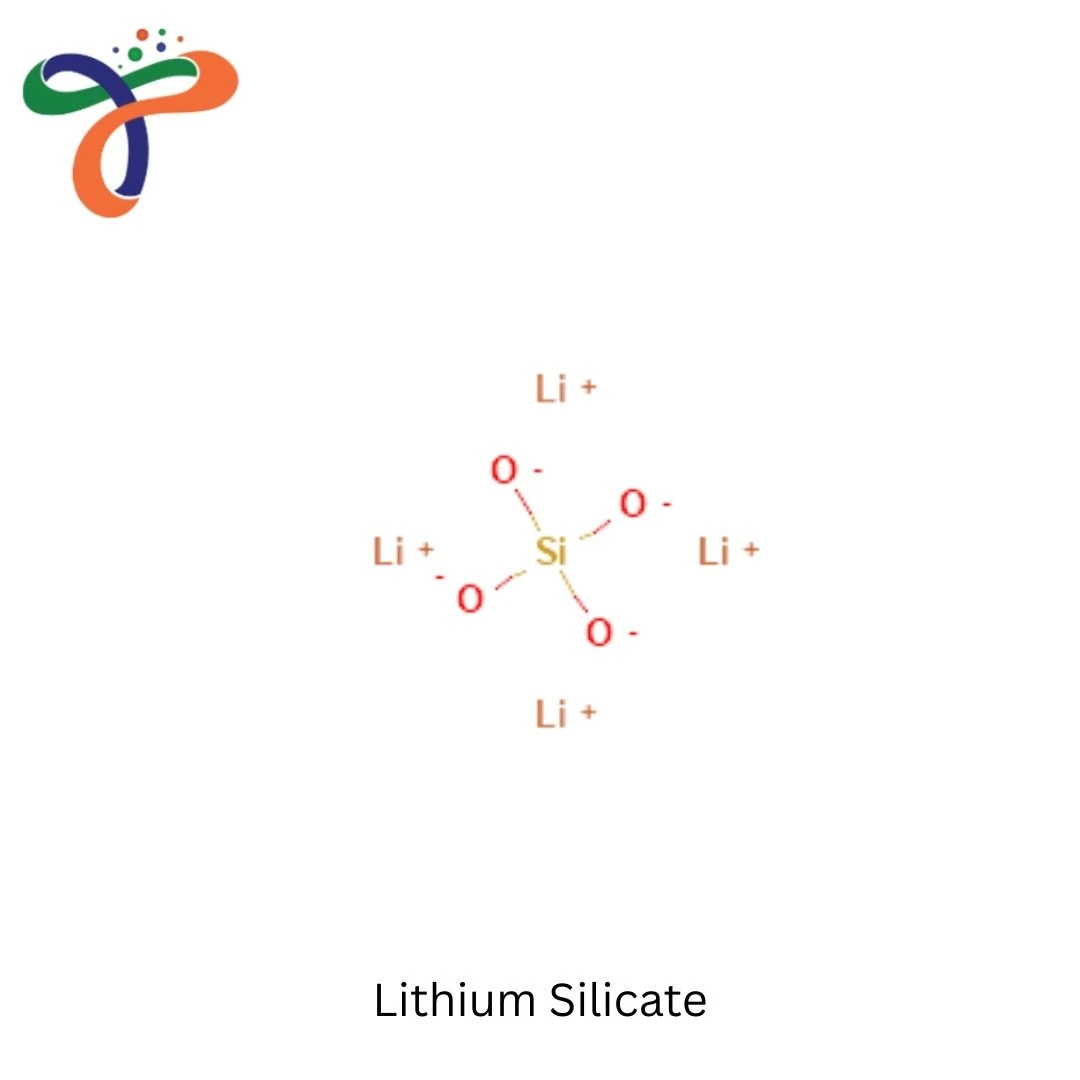

Molecular Formula :

LI4O4SI

Melting Point :

1110 °C

Boiling Point :

1800 °C

Solubility :

Insoluble In Water

Flash Point :

1000 °C

Description :

Overview of Lithium Silicate

Lithium Silicate is an industrial organic compound that is utilized for manufacturing and surface treatment applications where silicate-based performance is needed. It is typically utilized to increase the hardness of surfaces while also enhancing durability. It is also used for ensuring solid bonding in industrial processing systems. Lithium silicate is a preferred choice in applications where controlled penetration, constant performance, and stability over time are essential for the production output.

Lithium silicate vs sodium silicate is often compared in industry because lithium silicate generally offers better penetration and stable performance in certain industrial surface treatment applications.

Applications of Lithium Silicate

Surface Hardening & Concrete Treatment

Lithium Silicate is extensively used in the industrial process of surface hardening and concrete treatment when improved durability and resistance to abrasion are needed. It ensures a stable surface performance and long-term performance in industrial flooring and construction applications. It is typically used in conjunction together with Calcium Silicate to provide silicate-based industrial processing support.

Industrial Coatings & Processing Support

Lithium Silicate is used in industrial coatings and processing applications where stable bonding and consistent surface performance are required. It supports smooth application and reliable output quality in industrial manufacturing systems. It is often handled with Calcium Oxide depending on processing requirements.

Chemical Processing & Formulation Use

Lithium Silicate is used in chemical processing where silicate compounds support controlled formulation performance and stable manufacturing output. It helps maintain consistent processing behaviour in industrial setups. It is often used with Sodium Silicate for silicate formulation applications.

Specialty Industrial Manufacturing

Lithium Silicate is also used in specialty industrial manufacturing where stable silicate performance and consistent quality are required for long-term processing operations.

Safety & Handling Guidelines

-

Store in a cool, dry, and well-ventilated area

-

Keep containers tightly sealed and protected from contamination

-

Avoid direct contact with skin and eyes

-

Avoid inhalation of mist or dust during handling

-

Use protective gloves, goggles, and suitable clothing

-

Wash hands properly after handling

-

Dispose of packaging as per local guidelines

Where to Buy Lithium Silicate?

Lithium Silicate Manufacturer

Lithium Silicate is manufactured for industrial applications where consistent quality and stable performance are required for surface treatment and processing systems.

Lithium Silicate Supplier & Distributor

Lithium Silicate is supplied in industrial-grade quantities for manufacturers who require steady supply and consistent quality. As a reliable supplier and distributor, Chemicalbull Pvt. Ltd. supports customers with dependable sourcing, scalable volumes, and standard documentation for domestic and export requirements.

MSDS for Lithium Silicate

The MSDS for Lithium Silicate includes detailed information on safe handling the storage environment, exposure control First-aid measures, as well as emergency procedure for responding. Always read the MSDS before using.

Frequently Asked Questions (FAQs)

-

What is lithium silicate used for?

Lithium silicate is used for surface hardening, concrete treatment, industrial coatings, and silicate-based formulation applications. -

What is the formula for lithium silicate?

The formula for lithium silicate is commonly written as Li₂SiO₃. -

What is lithium silicate vs sodium silicate?

Lithium silicate is usually chosen for its superior permeation and a more stable surface and stability, while sodium silicate is typically employed in general silicate applications, based on the requirements of industrial applications.