Edta Zinc

Form :

Powder

Molecular Weight :

353.59 G/Mol

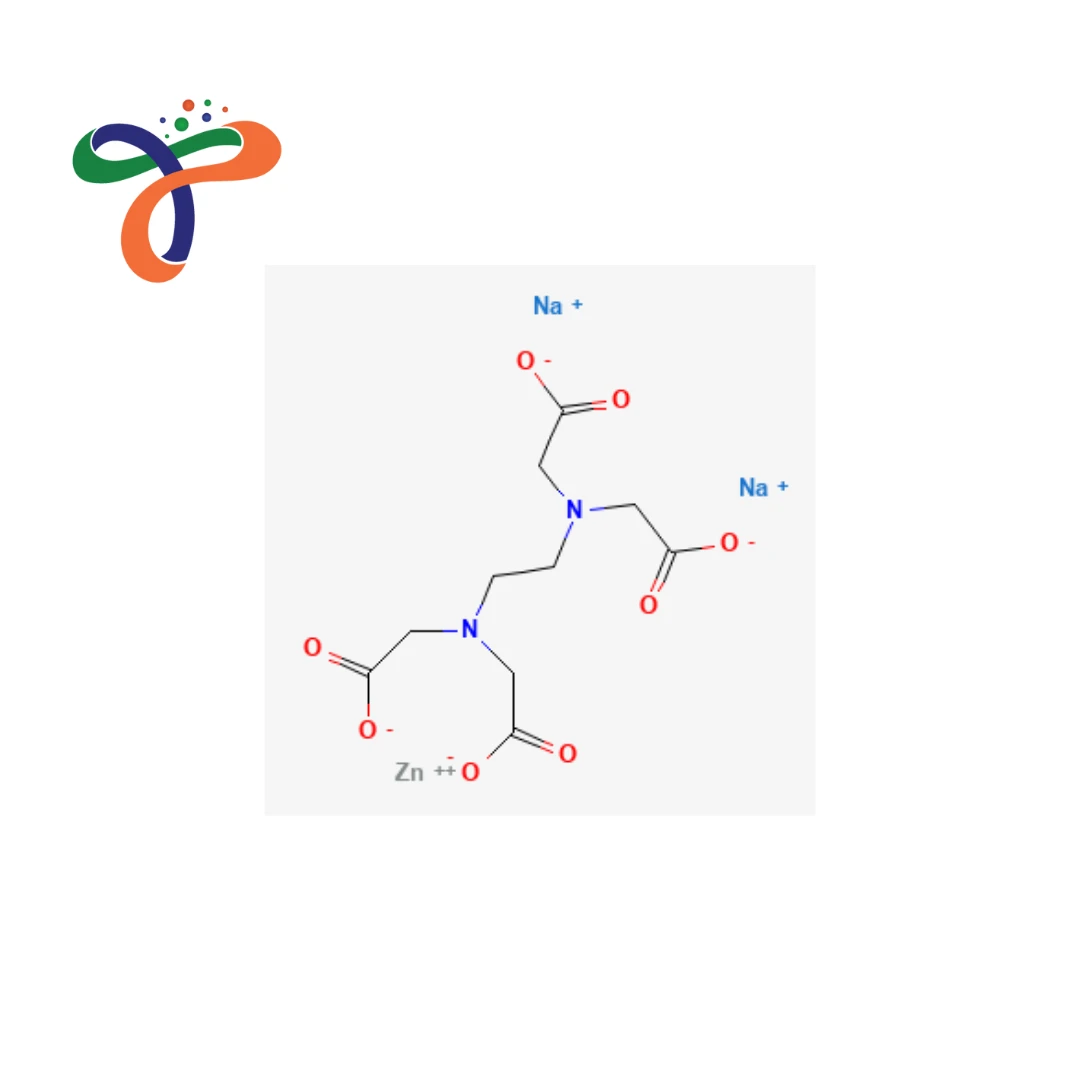

Molecular Formula :

C10H12N2NA2O8ZN

Melting Point :

290 °C

Boiling Point :

360 °C

Solubility :

Soluble In Water; Insoluble In Most Organic Solvents

Flash Point :

200 °C

Description :

Overview of EDTA Zinc

EDTA Zinc is a stable industrial chelated zinc compound formed by the coordination of zinc with ethylenediaminetetraacetic acid (EDTA). It is generally available in the form of a transparent to white crystal powder and is valued due to its very high solubility, chelation efficiency, and its controlled zinc availability within industrial processes.

A chemical used in industrial processes, EDTA Zinc is widely utilised in the formulation of micronutrients for chemical processing, electroplating, and other industrial speciality applications in which stable metal ions and consistency of performance are crucial.

Applications of EDTA Zinc

Water Treatment & Industrial Chelation

EDTA Zinc is widely used for the water treatment process of industrial plants to regulate zinc ion stability and avoid unintentional scale or precipitation. It aids in the efficient management of metals in cooling and process water systems. It is typically used along with EDTA Disodium Salt, EDTA Ferric Sodium, and Sodium Gluconate in the sequestration and chelation processes.

Chemical Processing & Speciality Industrial Formulations

In the chemical industry, EDTA Zinc is applied in special formulations in which controlled delivery of zinc and regulation of metal ions are needed. It aids in maintaining formulation stability and process consistency in complicated industrial systems.

Surface Treatment & Electroplating Applications

EDTA Zinc is utilised in electroplating and surface treatment processes to ensure uniform deposition of zinc and stability of baths. It is usually evaluated with zinc Sulphate, as well as EDTA Tetrasodium Salt Anahydrous, during controlled finishing of metal processes.

Safety & Handling Guidelines

- Keep in a cool, dry, well-ventilated location

- Seal containers well and keep them clearly labelled

- Avoid inhaling dust and contact with eyes or skin

- Use protective gloves, goggles, and suitable industrial clothing

- Handle under controlled industrial conditions

- Dispose of waste and packaging according to regulatory guidelines

Where to Buy EDTA Zinc?

EDTA Zinc Manufacturer

EDTA Zinc is manufactured for industrial-grade applications requiring controlled chelation strength, consistent zinc content, and reliable performance in water treatment and chemical processing industries.

EDTA Zinc Supplier & Distributor

EDTA Zinc is offered in large quantities as well as industrial packing formats for companies that require dependable quality and controlled handling. Purchase EDTA Zinc from Chemicalbull Pvt. Ltd., a reputable industrial chemicals distributor and supplier, providing clients with reliable sourcing, documents, and compliant logistics.

MSDS for EDTA Zinc

MSDS for EDTA Zinc includes detailed information on dangers, safe handling practices, store conditions, and exposure control. First-aid measures and emergency procedures for responding. Always read the MSDS prior to industrial use.

Frequently Asked Questions (FAQs)

What is the chemical formula of EDTA-Zinc?

EDTA Zinc is generally represented as C₁₀H₁₂N₂O₈Zn, depending on hydration state.

What are the uses of EDTA-Zinc?

EDTA Zinc is utilised in water treatment in the industrial sector as well as chemical processing, the electroplating process, formulations of micronutrients, and systems for metal ion chelation.

Is EDTA zinc water-soluble?

Absolutely, EDTA Zinc can be extremely water-soluble and therefore suitable for industrial liquid formulations as well as process systems.

Is EDTA Zinc hazardous?

EDTA Zinc is generally low hazard when handled properly, but standard industrial safety practices and MSDS guidelines should be followed.